I needed a way to tune monitor a washtub bass around other instruments and the mic on my tuner kept picking up the other instruments. Plus, I wanted a way to record from a ukulele that didn’t have a pickup. So, I built a pickup from a piezo transducer. It was pretty easy.

I used a piezo transducer from RadioShack (Part # 273-0073), some audio cable, a mono phone plug, a little heat shrink (optional), and epoxy putty. You can find audio cable, mono plugs, and heat shrink at RadioShack. Any hardware or hobby store will carry epoxy putty.

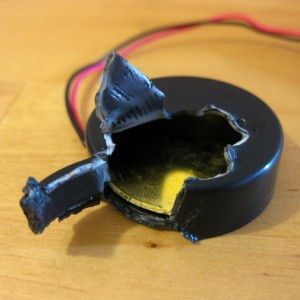

The hardest part of this project is extracting the piezo element from the plastic case it comes in. Luckily the plastic is rather soft and can be peeled away with pliers. I usually use pliers to rip off the little tabs on either side of the piezo. Then, I peel away the black plastic being careful not to damage the metal piezo element inside. I think the piezo element can take quite a bit of abuse though.

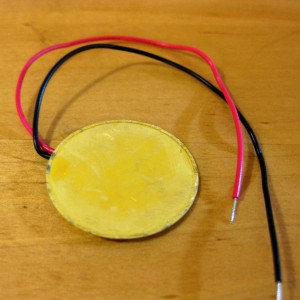

Next, the audio cable needs to be stripped and soldered to the piezo. You can desolder the wires that came with the piezo but you need to be very careful not to overheat the piezo. I prefer to solder on the new wires then, cut off the old wires close to the solder. That way, I am less likely to damage the piezo.

One wire in the audio cable carries the signal and is soldered to the center of the piezo. The other wire, the ground, is twisted together with the shield and soldered to the perimeter of the piezo.

The other end of the audio cable connects to the mono phone plug. Before doing so, don’t forget to slide the plug shield and heat shrink tubing onto the audio wire. The signal wire should be soldered to the smaller tab on the plug that connects to the tip of the plug. The ground wire and the shield should be soldered to the larger ground tab of the plug (see photo below). Then, slide the heat shrink tubing over the exposed wire and shrink the tubing with a heat gun or small flame from a lighter, candle, or match. Finally, screw the plug shield into place.

To finish things off, I made a nice covering for the top of the piezo element with epoxy putty. Epoxy putty is pretty easy to use. You just cut of a piece of it and kneed it until the color is uniform before using. You can shape it like you would clay although it is a little sticky and gets stickier as it hardens so you need to work fairly quickly. I would recommend wearing latex or rubber gloves when handling epoxy putty. It fully cures to a hard finish in 24 hours. It sands easily but creates a fine dust when sanded. I start sanding with 220 grit sandpaper and finish off with 600 or sometimes 1000 grit wet/dry sandpaper. You can paint epoxy putty too. A good oil-based enamel will put a nice, rugged finish on epoxy putty. Alternatively, you could dip the piezo in something like Plasti Dip. I haven’t tried dipping a piezo in it but it should work.

The pickup should be ready to go once the enamel dries. I use double-sided foam tape to attach the pickup to instruments. A 1/8″ to 1/4″ phono adapter may be needed to plug the piezo into some audio equipment but they are easy to find.

Here’s a demo video showing me using the pickup to tune a ukulele and then recording sound directly from the pickup. It works quite well and is dirt cheap!

Update (13 Dec. 2011)

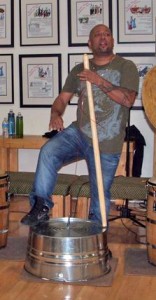

The piezo works great on an ukulele as shown in the video above but fails miserably on the washtub bass. The bass looks like the one pictured below. I’ve tried attaching the pickup to the top of the washtub and the metal bolt that connects the string to the top of the washtub but I can’t get a good signal. Anyone have any suggestions?

I suggest that you try mounting it on the post. Also, you need more flexing of the piezo. Instead of encasing one in the plasti-dip or epoxy.

Mount half of a transducer on small block (The side with wires on it) and allowing the other half to be in open space. You might be able to mount this in an Altoids box.

Then you need a capacitor about 0.01 mFd between the center tip of the jack and the transducer. This will allow the audio which has AC characteristics to pass into the audio device and it will prevent the DC portion from going in (which could actually damage equipment if you drop a transducer and it chucks out 90 VDC – which also might be blinding your tuner.

I wonder if it might be better to use a thin wood covering, like two thin pieces of veneer to sandwich the piezo element, instead of epoxy.

You have to find the largest piezo, 4 cm in diameter is 0, 5 thick is doing the same job, I’ve bought it in Germany, all right. Gabriele mari